Product

Recommended article

- Photovoltaic module efficiency testing equipment Provides High-Voltage, High-Power Performance Testing Solutions

- Forest Fire Detection Provides Automatic Meteorological Monitoring and Forest Fire Warning

- I-V Curve Tracer: Outdoor Measurement Equipment for Photovoltaic Module Current-Voltage Characteristic Testing

- Multifunctional weather station Technical Features and Application Fields

- EL Test Power Supply is used for batch EL defect detection and production testing of photovoltaic modules

- Ultrasonic Snow Depth Detector utilizes ultrasonic principles to achieve millimeter-level dynamic monitoring of snow thickness

Contact us

Shandong Fengtu IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

From Standard Compliance to Real-Time Monitoring: Fengtu Online Dust Particle Counter in Workshop Air Management

Article source:Weather station time:2025-09-15 09:29:46 viewed:244times

In the field of industrial production, numerous workplaces have extremely high requirements for the cleanliness of the workshop air environment. For instance, in pharmaceutical production workshops of the pharmaceutical industry, the presence of impurities in the air may affect the purity and safety of pharmaceuticals, posing risks to patients' health. In the electronics industry, tiny contaminants in chip manufacturing workshops can lead to chip performance failures and reduce product qualification rates. Similarly, food processing workshops also require a clean environment to prevent food contamination by airborne microorganisms and dust, thereby ensuring food safety. Beyond these, precision instrument assembly workshops, biological laboratories, and other facilities also need strict control over air cleanliness to guarantee the accuracy of production and experiments.

So, how is the cleanliness of a workshop determined? The key lies in the quantity and size of dust particles in the air. Dust particles are tiny solid particles suspended in the air, with diameters measured in micrometers, which are barely visible to the naked eye. Clean workshops in different industries have clear standards for the maximum allowable concentration of dust particles with specific particle sizes. Examples include the GMP standards for the pharmaceutical industry and the ISO 14644 standards for the electronics industry. Only when the concentration of dust particles is controlled within the range specified by these standards can the production requirements be met.

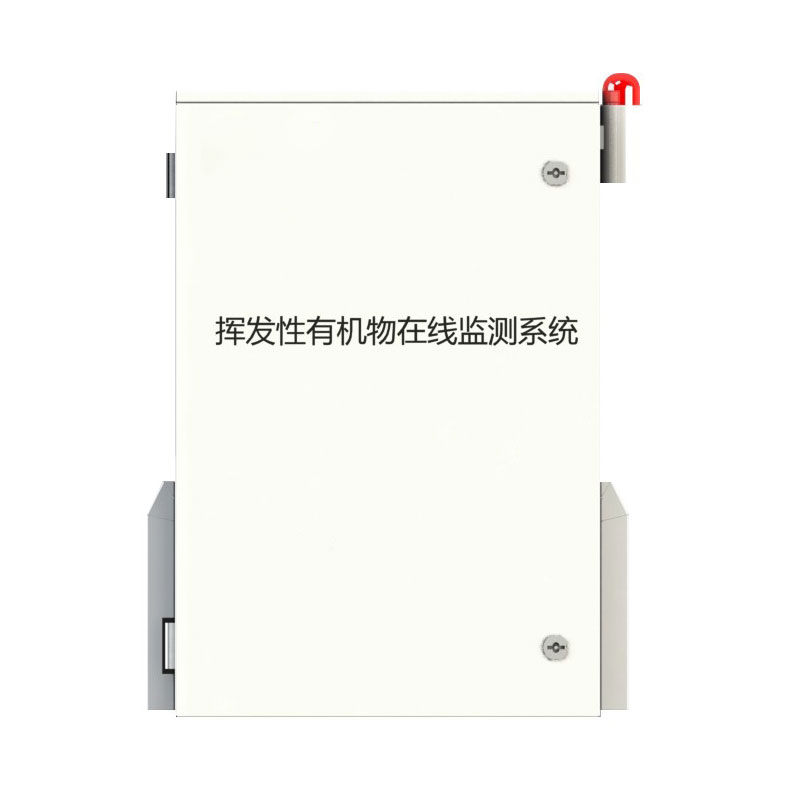

To accurately and real-time monitor the concentration of dust particles in the workshop air, specialized equipment is required – the Fengtu Online Dust Particle Counter. This device adopts the laser scattering principle, enabling it to quickly capture dust particles of different sizes in the air. Through a high-precision sensor, it converts the number of particles into digital signals, which are displayed in real-time on the device's screen. Additionally, it can be connected to a computer or a cloud platform, realizing data storage, analysis, and remote viewing.

It supports 24/7 non-stop online monitoring, eliminating the need for frequent manual operations. This not only reduces labor costs but also avoids the lag and errors associated with manual monitoring. The detection accuracy of the device complies with relevant national standards, accurately reflecting the air cleanliness status of the workshop and providing a reliable basis for enterprises to adjust their purification systems in a timely manner. Moreover, it is easy to install and can be flexibly placed according to the workshop layout, adapting to workshop environments of different scales and industries.

In conclusion, in the pharmaceutical, electronics, food, and precision manufacturing industries, the Fengtu Online Dust Particle Counter can assist enterprises in meeting industry standard requirements, improving product quality, and reducing losses caused by substandard air cleanliness.

This paper addresses:https://www.fengtuweather.com/industry/793.html

Related products

Related article

-

I-V Curve Tracer: Principles, Instrumentation and PV System Applications

2025-10-13 -

Vehicle-Mount Weather Stations: Small in Size, Big in Pollution Management Impact

2025-03-26 -

Essential Meteorological Parameters: The Foundation of Weather Forecasting and Climate Analysis

2024-11-04 -

Which IoT devices are suitable for weather stations?

2024-03-13 -

Fengtu Online dust Monitoring system: All-Weather, Multi-Parameter Precision

2025-11-10 -

Scenic Weather Station: Empowering Tourism with Meteorological Resources

2024-09-26 -

Vehicle-Mount Weather Station in Action: Tackling Meteorological Disasters Head-On

2024-12-05 -

Road Weather Station: Monitoring, Warning, and Ensuring Road Safety

2025-02-05