Product

Recommended article

- Photovoltaic module efficiency testing equipment Provides High-Voltage, High-Power Performance Testing Solutions

- Forest Fire Detection Provides Automatic Meteorological Monitoring and Forest Fire Warning

- I-V Curve Tracer: Outdoor Measurement Equipment for Photovoltaic Module Current-Voltage Characteristic Testing

- Multifunctional weather station Technical Features and Application Fields

- EL Test Power Supply is used for batch EL defect detection and production testing of photovoltaic modules

- Ultrasonic Snow Depth Detector utilizes ultrasonic principles to achieve millimeter-level dynamic monitoring of snow thickness

Contact us

Shandong Fengtu IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

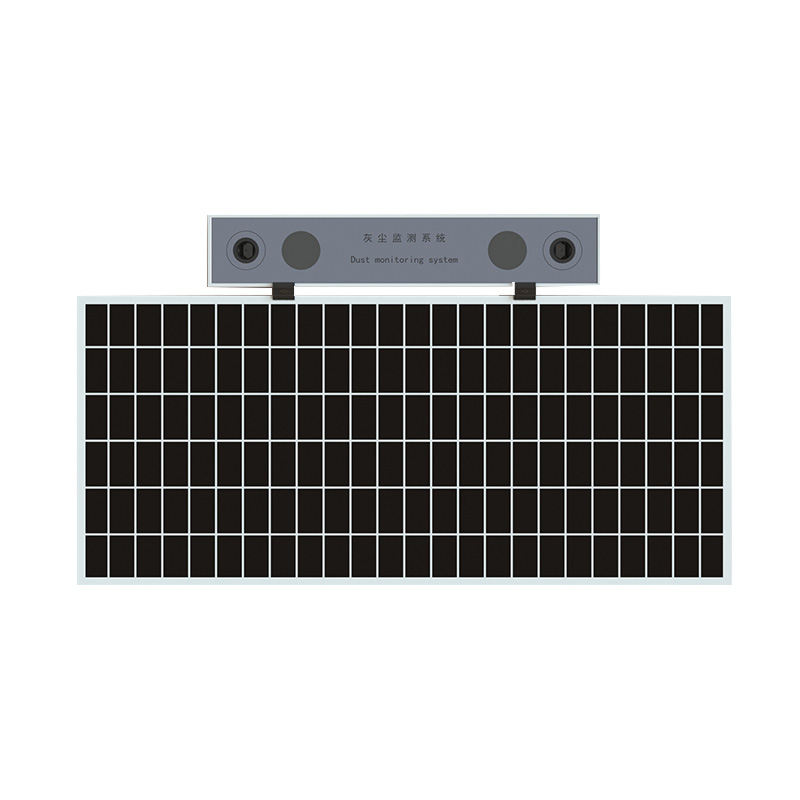

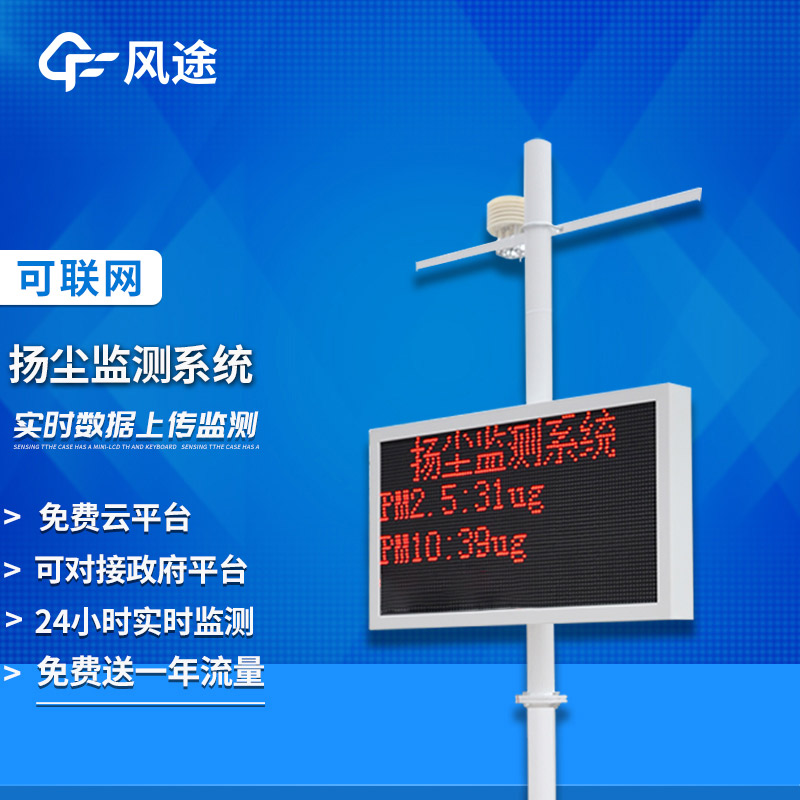

Dust monitoring system installation specification

Article source:Weather station time:2024-06-11 08:53:24 viewed:209times

To ensure the accuracy and effectiveness of dust monitoring at construction sites, the installation of dust monitoring systems must follow a series of carefully developed specifications:

1. the installation of the monitoring equipment should be located within the security fence of the construction area so that the main construction activity area can be fully monitored.

2. monitoring points should be located at the main entry and exit routes for construction vehicles as dust pollution from transport vehicles is more significant at construction sites, especially during deep foundation pit operations. If more than one monitoring point is required, at least one should be located at the main access road.

3. in order to avoid being affected by neighbouring sites, the monitoring point should not be set up on the boundary adjacent to other construction sites.

4. Monitoring equipment should be avoided in areas that may be affected by the direct action of wind or organic particulate emissions.

5. the monitoring point should be located away from any emission outlets that may produce grease and fumes in order to prevent grease and fumes from interfering with the monitoring results.

6. The monitoring point should be free of tall buildings, trees, or other obstructions that could impede air flow. The horizontal distance from the sampling port to the nearest obstruction should be at least twice the vertical distance of the obstruction above the sampling port.

7. The monitoring point should be selected in an area that is safe and has fire protection measures in place.

8. The monitoring equipment should be installed away from sources of strong electromagnetic interference to ensure the accuracy of the monitoring data.

9. The standard installation height of the particulate sampling port is recommended to be 3.5 metres above the ground to capture airborne particles more accurately.

10. Particulate matter sampling tubes should be kept vertical to ensure the representativeness and accuracy of the sampling process.

11. Monitoring instruments on site should be earthed in accordance with the electrical earthing code to ensure safe operation of the equipment.

12. After the monitoring instruments are installed, it should be ensured that there is at least 0.8 metres of operating and maintenance space around the equipment to facilitate regular inspection and maintenance.

This paper addresses:https://www.fengtuweather.com/industry/405.html

Related products

Related article

-

One - Stop Dust Monitoring Solution

2025-01-16 -

Road Weather Station & Matching Environmental Monitoring Cloud Platform: Monitoring, Early Warning and Traffic Safety Guarantee

2025-08-25 -

10-Component Dust Monitoring System for Playgrounds: Precision Tracking of PM2.5, PM10, and Meteorological Factors

2025-05-23 -

What is a speeding photo solar display?

2024-04-19 -

Advantages of online noise detectors

2024-03-29 -

Principles and Applications of Online dust particle counter

2025-11-21 -

Negative Oxygen Ion Monitoring System Builds Scenic Image

2024-04-16 -

The Structure, Advantages and Applications of Negative Oxygen Ion Monitoring Station

2025-09-17